Why Choose Us

Ambey Textles would have never had the ability to taste sweet achievement, achievement the proceeded with confidence and backing of our hold dear customers and business accomplices. All around weaved group of specialists, incredible quality makers, best in class specialized devices give convenient administrations, precise data.

The handloom business is the biggest house industry in the area and it gives amplest parkway to job opportunities just alongside horticulture, prime push has been given to execution of plans for advancement and improvement of handloom division.

Right from the first arrangement period ‘co-agent’ has been thought to be the perfect infrastructural foundation for usage of different plans for improvement of decentralized cabin industry like handlooms. All plans are along these lines detailed co-agent arranged. Accentuation has likewise been endless supply of co-agents with handloom weavers.

Our Vision is to make esteem for organizations through our capable group of experts and by utilizing the most recent data about the hamdloom.

In contact with style, Worldwide: Monitors worldwide design patterns and issue rules on pantone shades that are prominent.

Product : Carpets, Rugs, Cushions, Bath/Door mats, Throws.

Eco-accommodating : Uses just AZO free chemicals and vegetable colors.

Socially mindful: Ensures no youngster work is included at any phase of its operation.

Quality : Pure cotton yarn and silks utilized as crude material.

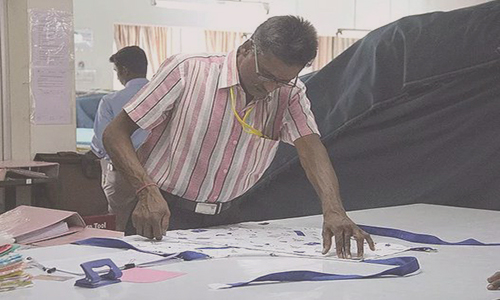

Manfacturing Process

Making Rugs By Hand

A hand knotted or hand woven rug represents the remarkable achievement of many highly skilled artisans. There are few, if any, other items you can purchase for your home on which more care and handwork has been lavished.

Every stage of this ancient craft, from spinning the wool to trimming the pile of the finished rug, is carried out by hand – not out of stubbornness but because there is no better way of making a rug.

Many modern rugs are described as hand tufted or hand finished. These are made by the much less intensive process of hand gluing yarn onto a base material, producing a rug that is inexpensive to make, but has a short life and is difficult to repair.

Every piece at The Rug Company has been crafted by hand in the same way that it always has been, except to this rich tradition we have added the best designs for our contemporary world.

SAMPLING – Given that what we do is such a visual process, we understand that clients may best be able to place orders with confidence only once they themselves have seen the product. Therefore, we present physical collections for customers to choose from, and then work on customizing the collections to suit their specific requirements.

Our Sampling team puts together all the details and ensures timely delivery of customized samples. Customized sampling usually completes within three to four weeks. Our commercial production closely mirrors the samples.

DYEING – We use Vat and Reactive dyes of international standards and offer color fastness standards that are commercially approved. Colour fastness to rubbing, washing and light is tested for each dye lot. We can closely match colors that are specified by our customers. Our Production Managers personally supervise this process and ensure that all standards are being met.

WEAVING – We use powerlooms and autolooms to weave our fabric. Again, our Production Managers are personally tasked with ensuring the high quality of the resultant fabric.

PRINTING – We offer printed designs using from table screens to rotary machines, each one suited to volumes and design specific needs. Our work includes even 20 screen work of a highly intensive nature resulting in wonderful reproductions.

VALUE ADDITION – Embroidered items are produced on hand guided machines as well as multihead computerized machines.

Products are also offered with beadwork, different trims, tassels, laces, sequins and other embellishments.

Various stitching techniques are used such as smocking, pleating, pin tucking, quilting etecetra.

STITCHING – Ambey Textiles is home to a team of highly-skilled tailors, whose expert needlework can be found on everything from simple, hemmed tablecloths to bags with intricate bead work. Their work is supervised by Quality Controllers who constantly check the product to ensure standards are being met. meets International Social Audit norms, and has been suitably accredited.

INSPECTION – All production, from fabric to made-up products, is inspected by our Quality Assurance team. Strict quality control is the norm, and AQL standards are used.

PACKING – This is a highly labor-intensive process. Our Supervisors monitor the packing team to ensure correct packing methods are followed, as well as making sure that correct labels and hang tags are in place, and other packing instructions are followed.

DISPATCH – Products are packed in export-ready cartons and dispatched generally from the Panipat (Haryana) , where our team overseas the timely completion of Customs documentation and shipment of the goods. We offer a highly competent Clearing and Forwarding Service, but are also amenable to working with the customer’s nominated forwarders.